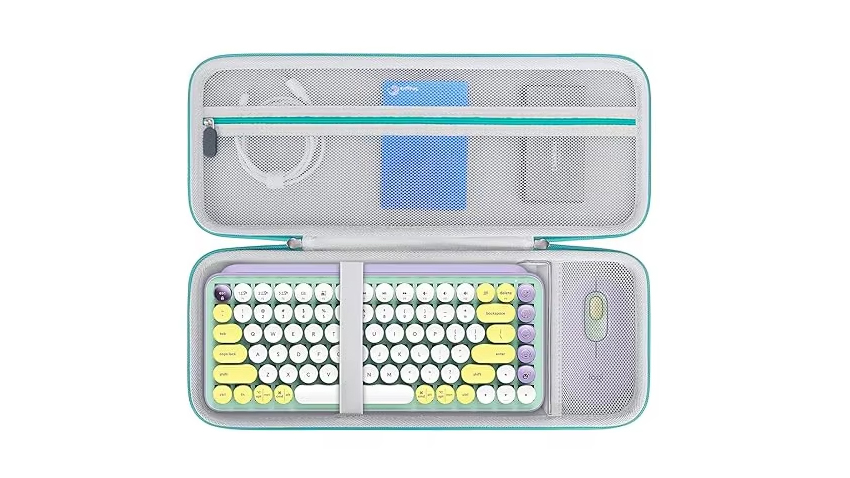

EVA Keyboard case production process

EVA Keyboard Case Production

1. Material Preparation

Select EVA Material: Choose high-quality, lightweight, and durable EVA.

Ensure Material Properties: Verify shock-absorbing, waterproof, and eco-friendly characteristics.

2. Design and Mold Creation

Design Case Dimensions: Precisely measure and design for specific keyboard models.

Create Mold: Develop mold based on design specifications for accurate shaping.

3. Cutting and Assembly

Cut EVA Material: Use precision cutting techniques to match mold dimensions.

Assemble Components: Attach zippers, pockets, and fasteners securely.

4. Quality Control

Inspect Cases: Thoroughly check each case for defects or imperfections.

Test Functionality: Ensure shock resistance, water resistance, and durability.

5. Packaging and Dispatch

Secure Packaging: Safely package cases to prevent transit damage.

Ship to Customers: Dispatch orders to customers or retailers as required.

Recommend news

Luxury Laptop Bags

02/02/2026

Related information

02/02/2026

Apple Leather Laptop Bag: Sustainable Elegance for Modern Professionals

Luxury Laptop Bags

01/19/2026

Mini Digital Storage Case: Small Size, Big Convenience

Mini Digital Storage Case

Contact Us

Contact: Roger Young

Tel: +86 13829257690

Email:sale@chfine.com

Address: 72#,Dongbao Road,Houjie Town,Dongguan,Guangdong,China.

JOIN TEAM

Be the first to get new knowledge

FOLLOW

Chfine(CN) | EVACAMARA CASE | RX packaging

COPYRIGHT @ 2022 ,Dongguan Chfine Luggages And Cases Co., Ltd. All rights reserved