Beauty Device Storage Bag Industry Insights: From Craftsmanship to Procurement and Compliance

I. Product & Craftsmanship (Manufacturing & DFM)

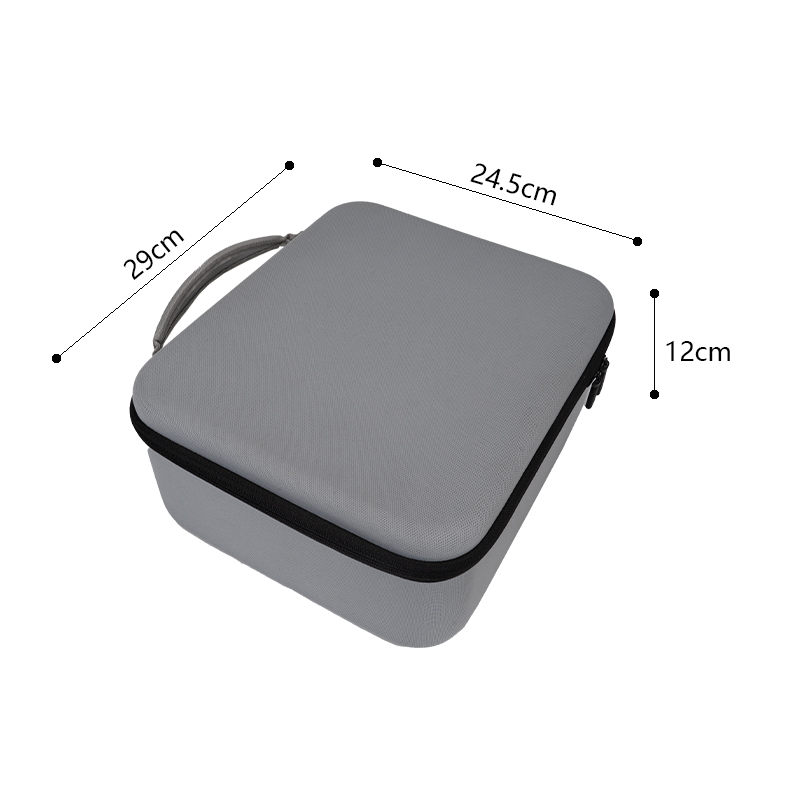

Beauty device storage bags are typically designed for portability, protection, compartmentalization, and display. They are commonly used for facial cleansing brushes, RF devices, hair removal devices, or importers, and serve to protect against shock, scratches, and moisture.

1) Structure & Material Selection

Shell

EVA thermoforming: lightweight, high strength, impact resistant; often covered with PU, synthetic leather, nylon, or Oxford fabric. Good for mid-to-high-end custom shapes and gift box feel.

Soft pouches: nylon/microfiber/velvet, low cost, fast lead time, suitable for accessories or entry-level devices.

Hard cases (ABS/PC/PP): stronger water resistance and compression strength, used for high-value devices or multi-component kits.

Inner lining & protection

EVA, cross-link foam, pearl cotton inserts; or flocked velvet, microfiber for scratch resistance.

Mesh pockets, elastic bands, Velcro modules to secure devices and adapters; main device should be fixed once, sharp components double-secured.

Hardware & accessories

Zippers: #5 nylon zippers are common; water-resistant designs use reversed zippers with PU-coated tapes; pulls can be customized with logos.

Handles/straps: reinforced with backstitching or bartacks.

Logos: screen printing, heat transfer, hot stamping, debossing, metal plates, epoxy labels.

2) Key Processes & Quality Control

Thermoforming (EVA): mold → forming → trimming → lamination → stitching.

Focus on surface flatness, seam uniformity, symmetry, and zipper smoothness.

Sewing & edging

Stitch density: 8–10 SPI; stress points require tighter stitching or backstitching.

Binding: neat, no fraying; leave tolerance to avoid bulging.

Assembly & functional testing

Must fit maximum tolerance size of device; cables require ≥1.5× coil space;

Sharp parts separated by ≥3mm padding; zipper cycles ≥3,000 without jamming.

Durability validation

Surface abrasion: Martindale >15k cycles as reference;

Drop/compression: full load dropped from 1m with no device damage;

Color fastness: ≥grade 4 to sweat/rubbing.

Water resistance

Most soft bags are splash-proof (PU/DWR coating); hard cases may add sealing strips for higher waterproof performance.

3) Manufacturability & Cost Drivers

Tooling: EVA requires molds; complex shapes, patterns, and logo placement increase cost and lead time.

Material yield: irregular designs, multiple compartments, and long binding lines increase scrap and labor.

Customization: branded pulls, metal plates, or trays increase MOQs and complexity.

II. Procurement Guide (Sourcing & Supplier Management)

1) Supplier Evaluation Checklist

Certifications: ISO 9001; social compliance (BSCI, SEDEX); environmental (ISO 14001 if available).

Material compliance: REACH/SVHC, phthalates, nickel release; third-party reports available.

Sampling ability: supports DFM review; sample turnaround ≤7–14 days.

Quality assurance: IQC, in-process inspection, outgoing QC; AQL 2.5/4.0 common.

Flexibility: standard lead time 25–35 days; peak-season capacity planning; reorder agility.

Cost transparency: BOM breakdown, labor cost, mold amortization, cost-down roadmap.

2) Sampling & Mass Production Flow

Freeze requirements: device size/tolerance, accessories, brand visuals (PMS color, logo method), target price & lead time.

DFM review: confirm insert slots, compartments, zipper path, binding layout.

Engineering samples (EVT): test fit, drop, zipper life; collect risk list.

Pilot run (PVT): validate tooling, process stability, and inspection standards.

Mass production (MP): 3-step inspections; document FAI/COC.

3) Cost & Lead Time Drivers

Material grade (PU coating, nylon denier, lining weight, foam density);

Eco-materials (rPET/GRS);

Design complexity (openings, compartments, binding length);

Customization (logo molds, MOQ);

Packaging (color box, blister, inserts);

Testing & certifications;

Seasonality (pre-peak capacity reservations).

4) Red-Line Quality Checks

Zippers smooth, no skipped stitches;

Corners intact, no collapse;

Compartments neither loose nor too tight;

Sharp parts double-isolated;

No color transfer; logo centered;

Easy one-hand device removal.

III. Compliance & Industry Trends

1) Regulations & Buyer Requirements

Chemical compliance:

EU REACH/SVHC: phthalates, azo dyes, nickel release;

California Prop 65: phthalates, heavy metals;

PFAS restrictions: fluorine-free water repellents trending.

Sustainability & packaging:

Recycled claims require GRS certification;

Packaging compliance under EPR and plastic taxes.

Physical safety:

Prevent small parts detachment, nickel allergy risk, poor colorfastness, or odors.

2) Sustainability & Design Trends

Material shift: rPET (GRS), water-based PU, bio-based PU/TPU, fluorine-free DWR.

Design for recycling: fewer composites, detachable metal, single-material preference.

Digital traceability: QR batch codes, material lot records, pilot “Digital Product Passport (DPP)” models.

Compliance-first: lock RSL before BOM freeze.

3) Testing & Documentation

Files: BOM, MSDS, COC, compliance declarations, incoming certs.

Tests: color fastness, abrasion, PU hydrolysis, odor/formaldehyde, phthalates, azo, nickel release, heavy metals.

Inspection: AQL 2.5/4.0; define major defects (dents, bubbles, open seams, zipper issues).

IV. Quick Spec & Quotation Template

Requirement Sheet

Device & accessories: __________ (max dimensions/weight)

Bag type: EVA / soft pouch / hard case

Outer material & color: __________ (PMS code)

Inner lining & compartments: slots/mesh/elastic/Velcro

Zipper: #5 reversed water-resistant / standard; custom pulls Y/N

Logo: screen print / heat transfer / deboss / metal plate

Sustainability: rPET (GRS) / fluorine-free DWR / water-based PU

Testing: REACH/SVHC, phthalates, color fastness, nickel release

Packaging: color box / e-commerce pack / inserts

Target price & MOQ: _____ pcs (pilot) / _____ pcs (mass)

Lead time: samples __ days; production __ days; trade terms EXW/FOB/CIF

V. Supply Chain Execution Checklist

RSL at project start: integrate restricted substances into specs.

Pre-sample tests: EVT with drop/zipper life, PU hydrolysis pre-check.

Material library: compliance white-list with historical test reports.

Cost breakdown: BOM, labor, scrap, tooling, test & inspection.

Sustainability option: always offer rPET/GRS + fluorine-free option.

Capacity lock: book production 8–10 weeks ahead of peak.

Traceability: keep lot numbers, test reports, FAI & OQC files.

Conclusion

Beauty device storage bags are evolving from simple accessories into value-added brand carriers. They not only protect and organize devices but also serve as a compliance and sustainability touchpoint. Anchoring in craftsmanship & manufacturability, systemizing procurement processes, and aligning with compliance & eco-trends helps companies compete beyond price, ensuring consistent delivery and brand trust.

Recommend news

EVA Storage Boxes

11/24/2025

Related information

11/24/2025

EVA Storage Boxes: A Modern Blend of Protection, Style, and Practicality

EVA Storage Boxes

Contact Us

Contact: Roger Young

Tel: +86 13829257690

Email:sale@chfine.com

Address: 72#,Dongbao Road,Houjie Town,Dongguan,Guangdong,China.

JOIN TEAM

Be the first to get new knowledge

FOLLOW

Chfine(CN) | EVACAMARA CASE | RX packaging

COPYRIGHT @ 2022 ,Dongguan Chfine Luggages And Cases Co., Ltd. All rights reserved